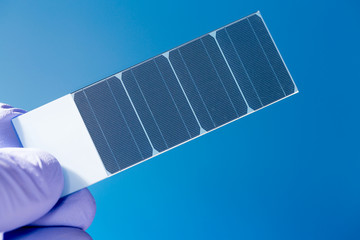

An alumnus of Keller Graduate School of Management in Phoenix, Arizona, Steve Verschoor is a seasoned entrepreneur and engineering professional who co-founded GTSP Global. As head of sales, Steve Verschoor oversees the solar manufacturing company’s sales team and has landed a slew of polysilicon and solar company deals worldwide.

Researchers have made significant progress in developing solar cells made from organisms. This novel technology is called a biogenic solar cell. These genetically modified cells can work in low-light conditions and have great potential to augment existing technologies in the future. The objective of this study is not to replace existing solar power-generating materials but to increase solar yields in places where sunlight is of very low intensity.

Solar energy is the most flexible renewable energy source, with a greater return on investment than either wind or hydropower. Wind and hydropower can meet various demands, but solar energy can transform society and human lives if used efficiently. Research is ongoing with the primary goal of reaching solar technology’s full potential.